Introduction:

The heart of numerous enterprises beats in their manufacturing processes, a complex journey that begins with product ideation and raw material procurement to production scheduling and quality control. To succeed in today's competitive landscape, manufacturers need tools that can help them manage the efficiency and productivity of these complex processes seamlessly. One powerful tool that has been helping manufacturing companies achieve these goals is Odoo ERP (Enterprise Resource Planning) software.

In this blog, we'll take a dive into the world of manufacturing in Odoo, exploring its key features and how they can empower businesses to optimize production, improve quality, and boost overall business performance.

Key benefits of Odoo ERP for Manufacturing

- Improved Production Planning and Scheduling

- Bill of Materials (BoM) and Work Center Management

- Quality Control and Equipment Management

- Reports and Analytics

Improved Production Planning and Scheduling

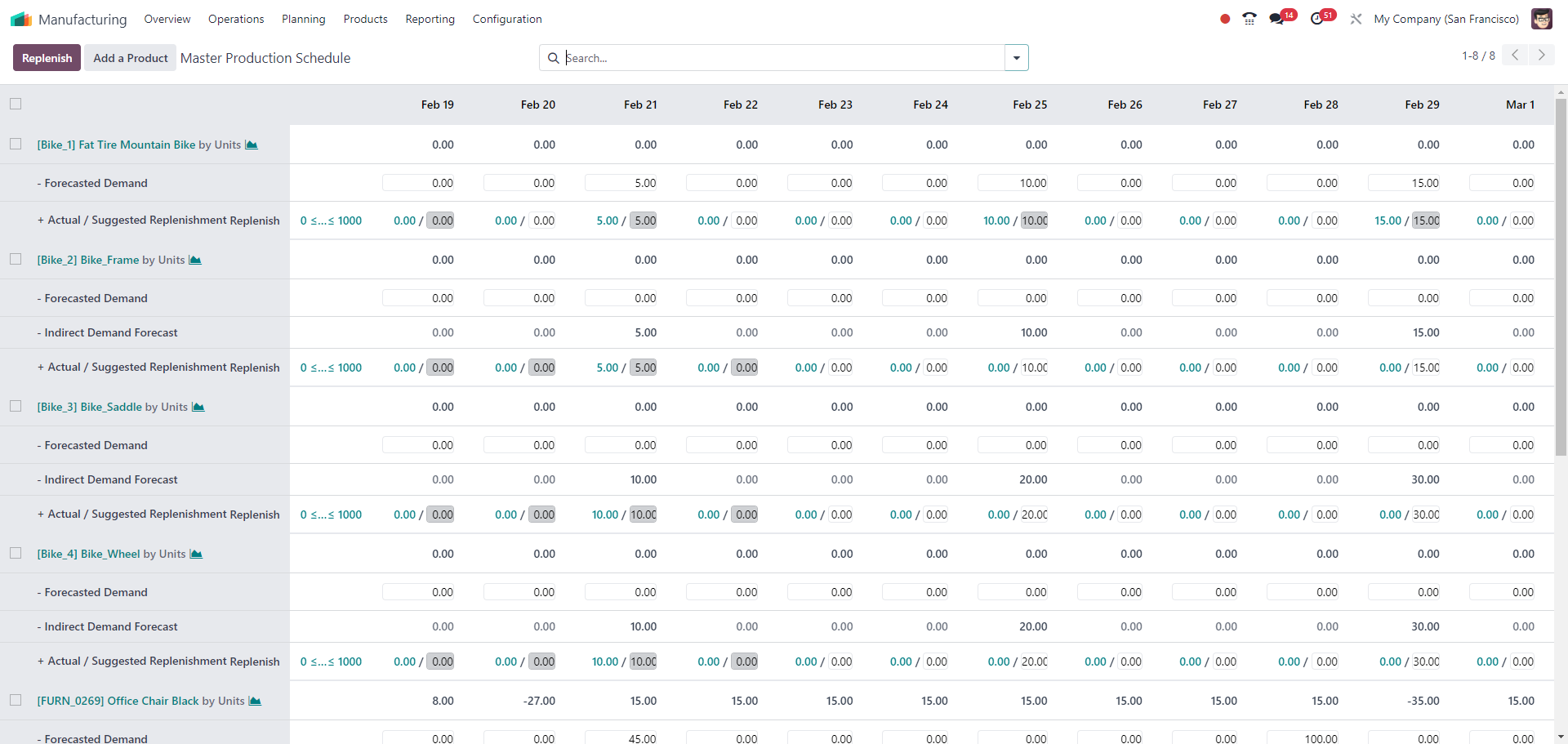

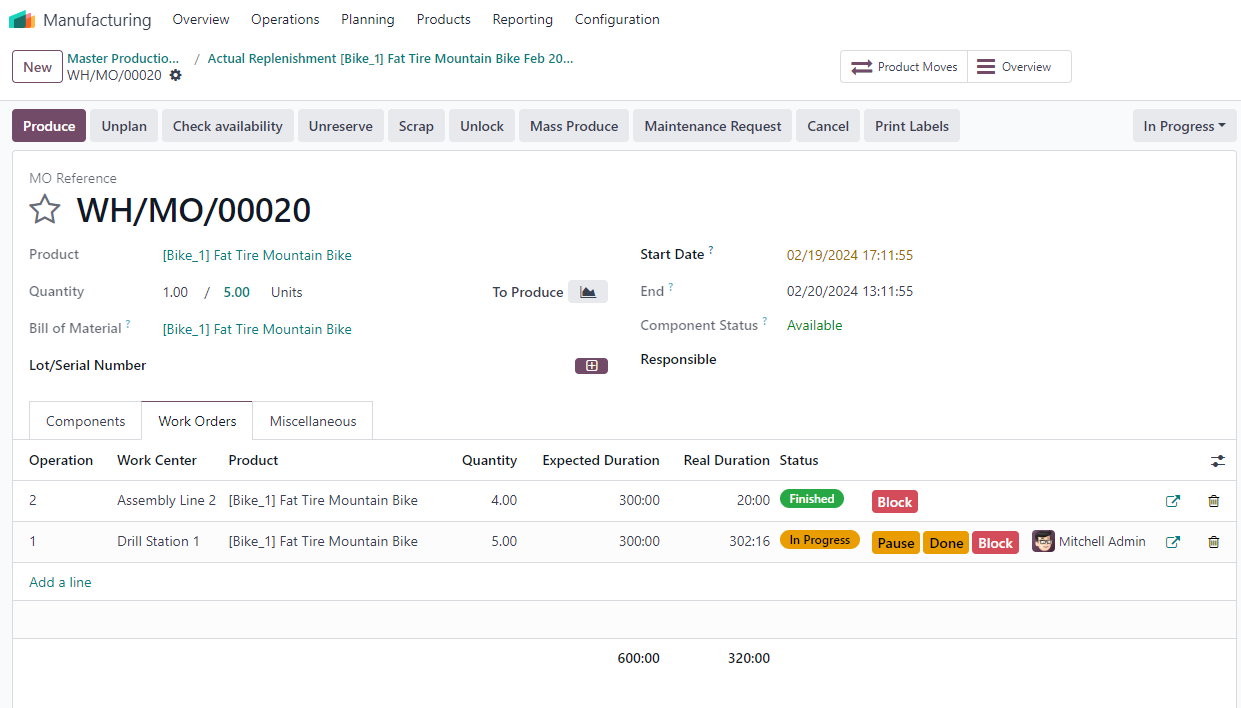

An effective production plan is a key of successful manufacturing. Odoo's Manufacturing module helps manufacturers plan and schedule production based on sales orders, demand forecasts, and stock levels, ensuring that resources are allocated efficiently and delivery deadlines are met.

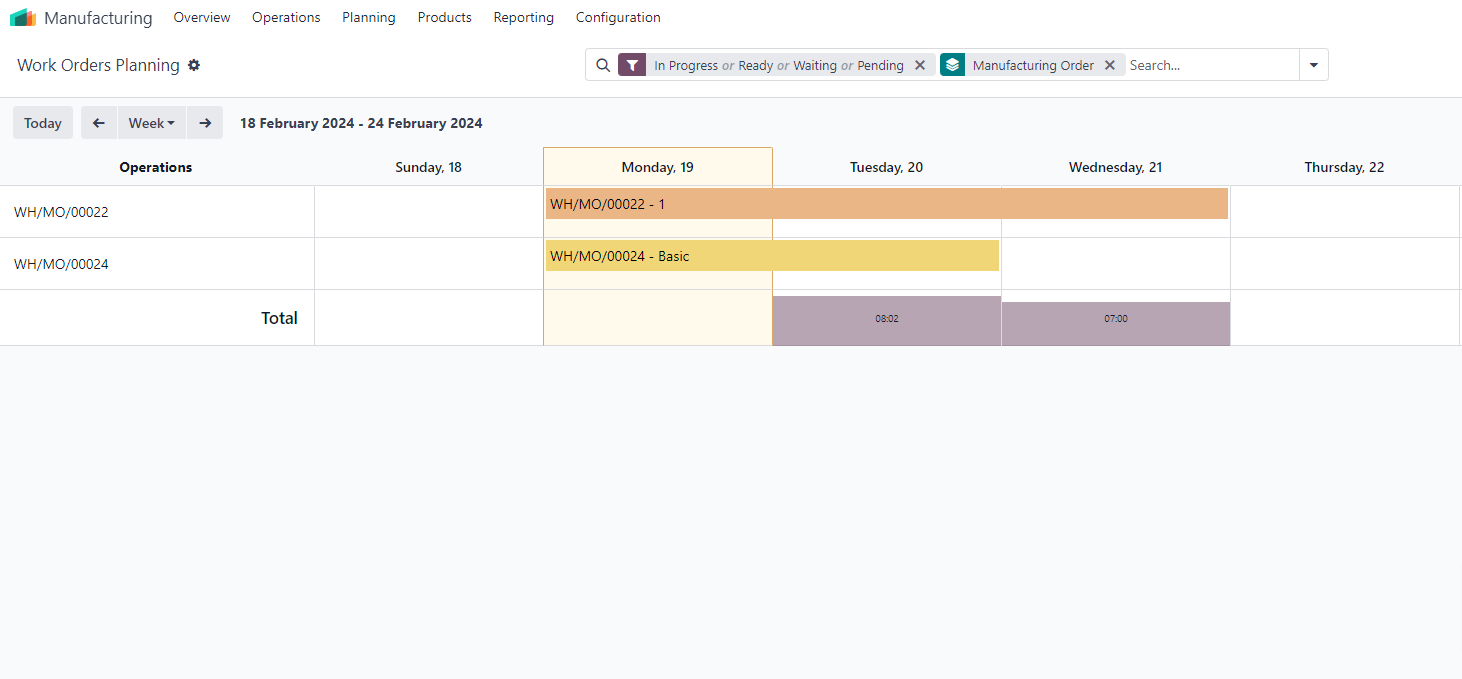

Odoo offers various planning methods, including Make to Order (MTO) and Make to Stock (MTS). With real-time visibility into production workflows, manufacturers can optimize resource utilization, minimize bottlenecks, and meet customer demands efficiently by demand forecasting. Plan and schedule your production using the following operations.

- Master production schedule: Estimate your demand and Launch replenishment

- Plan by Production

- Plan by Work center and Plan work order by dependencies

- Real-Time Production Schedular

Bill of Materials (BoM) and Work Center Management

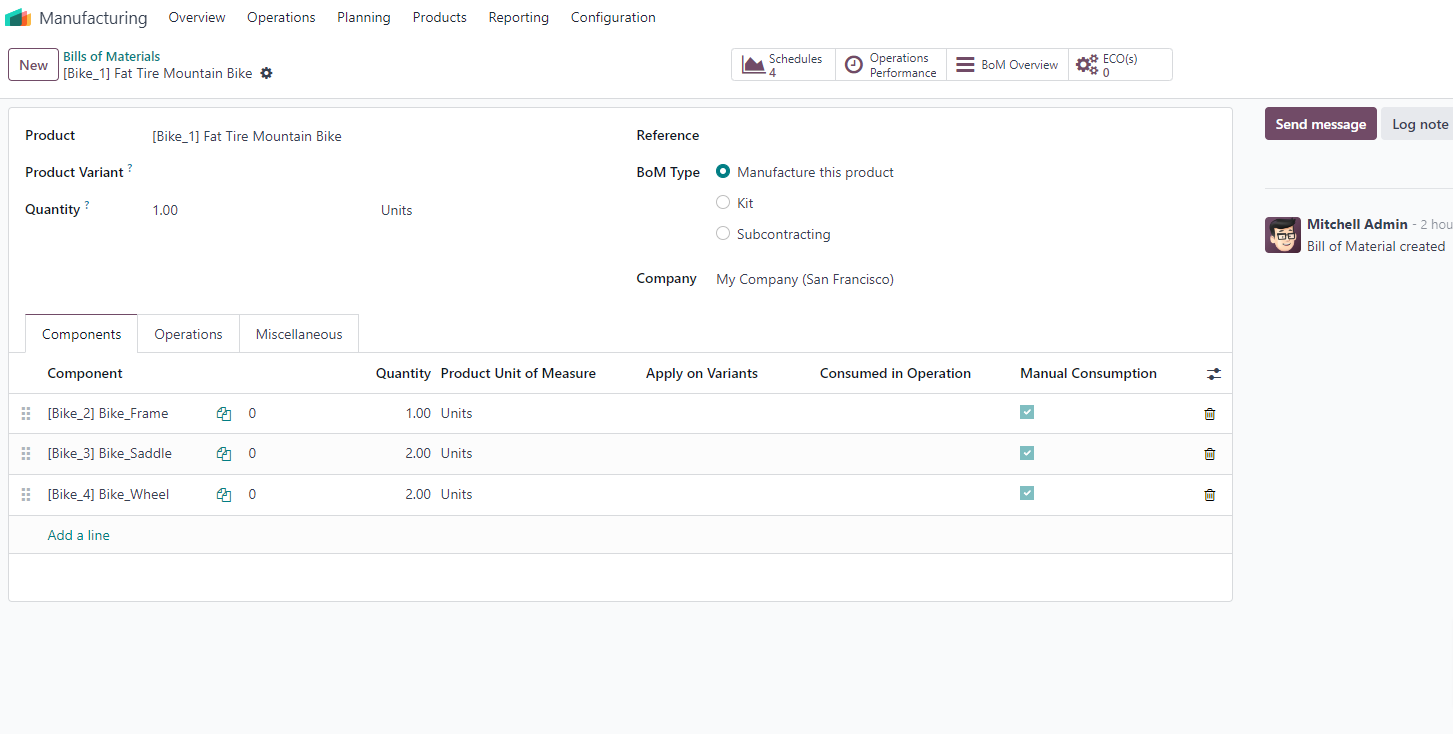

Odoo allows manufacturers to create and manage detailed Bill of Materials for their products. This includes defining the components, quantities, subassemblies, and routing (work sequences) required to produce a finished product. These BOMs can be multi-level, enabling the management of complex product structures.

- Set up a bill of materials (BOM)

- Different BOM Type: Manufacturing, Kit, Subcontracting

- Use kit to manage the complex product

- Configure semi-finished products

- Work center classification

- Set up operations with specify Work center

Quality Control and Equipment Management

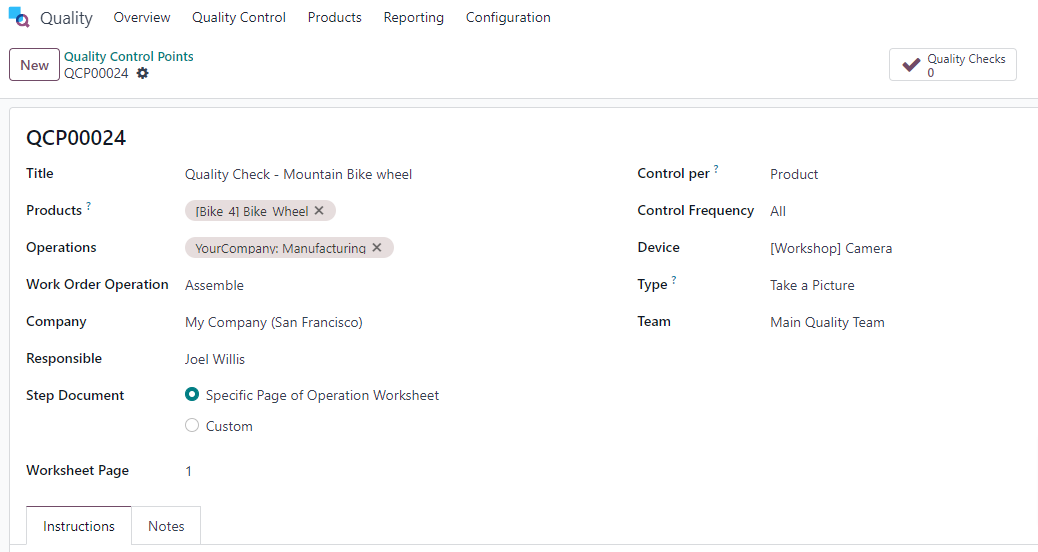

Quality control module in Odoo allows manufacturers to define quality control points and inspection criteria for products. It ensures that products meet quality standards before they leave the production line. This involve inspections, testing, and documentation of quality processes and Odoo provides robust tools for businesses to streamline their equipment management processes.

- Configure Quality Control Points

- Control per: Operations, Product, Quantity

- Control Frequency: All, Random, Periodic

- Type of Quality check points: Instructions, Take a Picture, Register Production, Pass - Fail, Measure or Worksheet

- Custom Quality Alerts

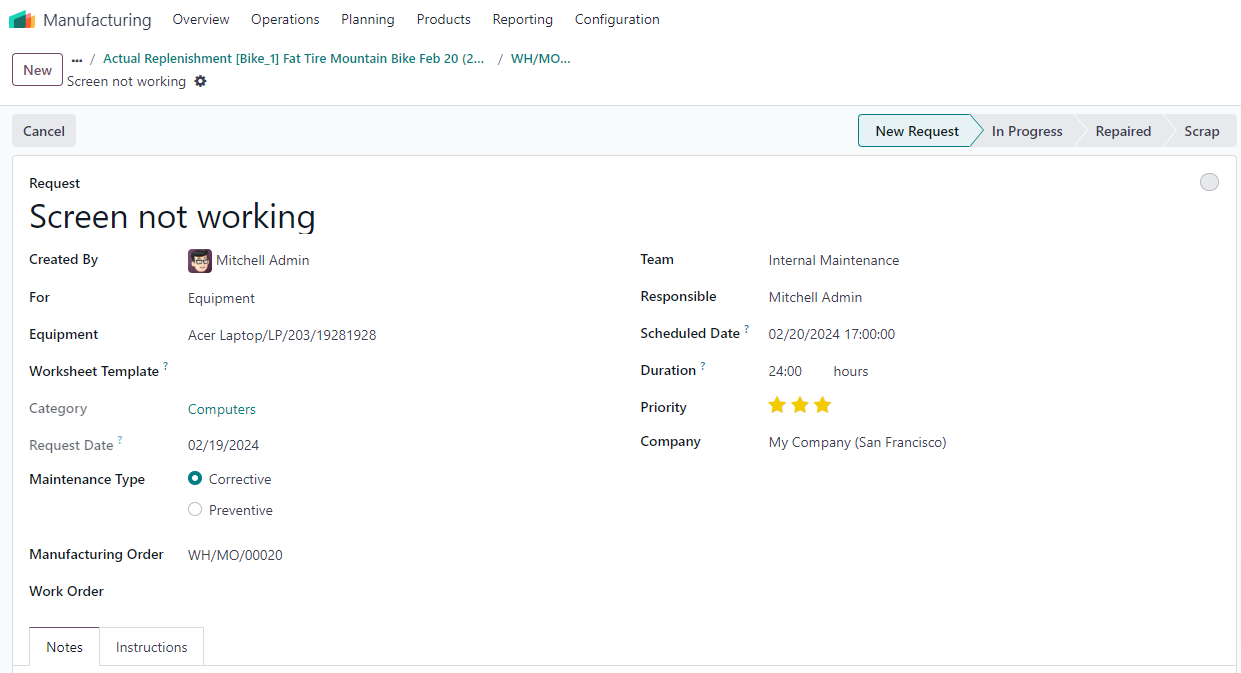

- Equipment Maintenance : Machines & Tools

- Generate Maintenance Request

Reports and Analytics

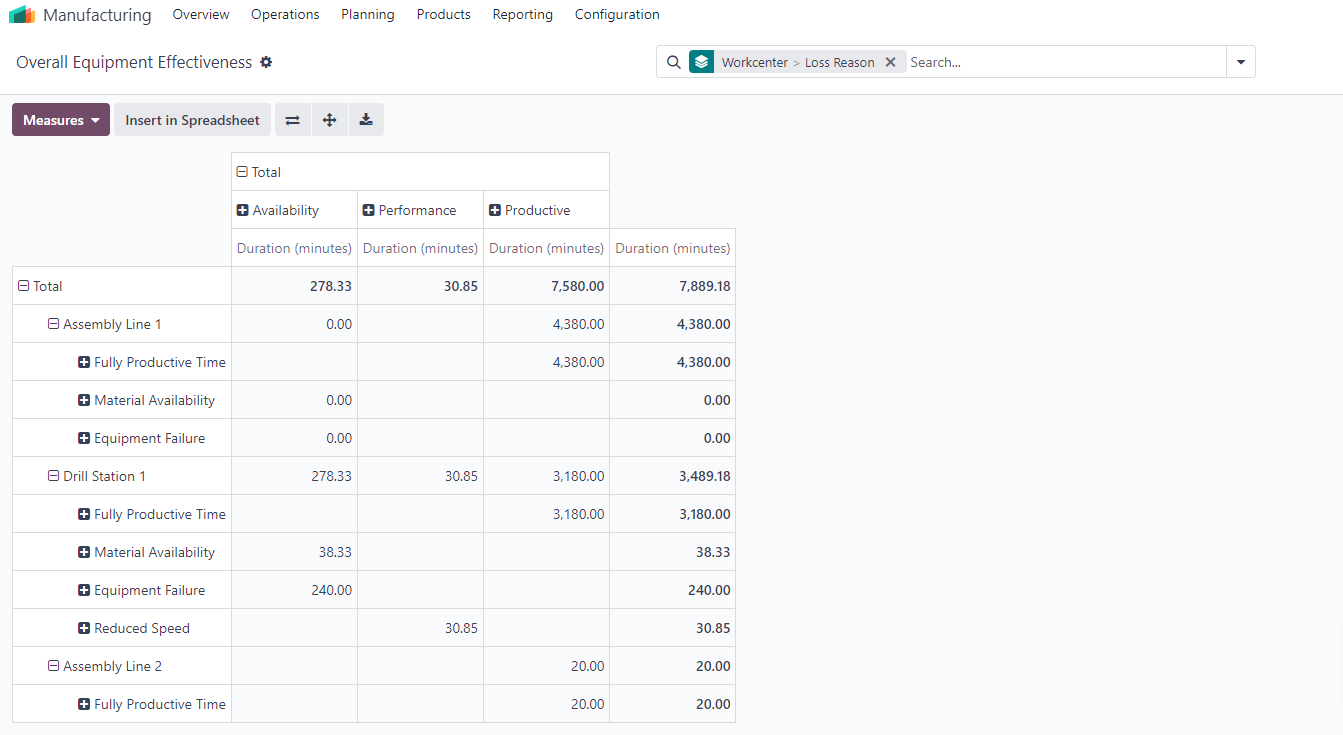

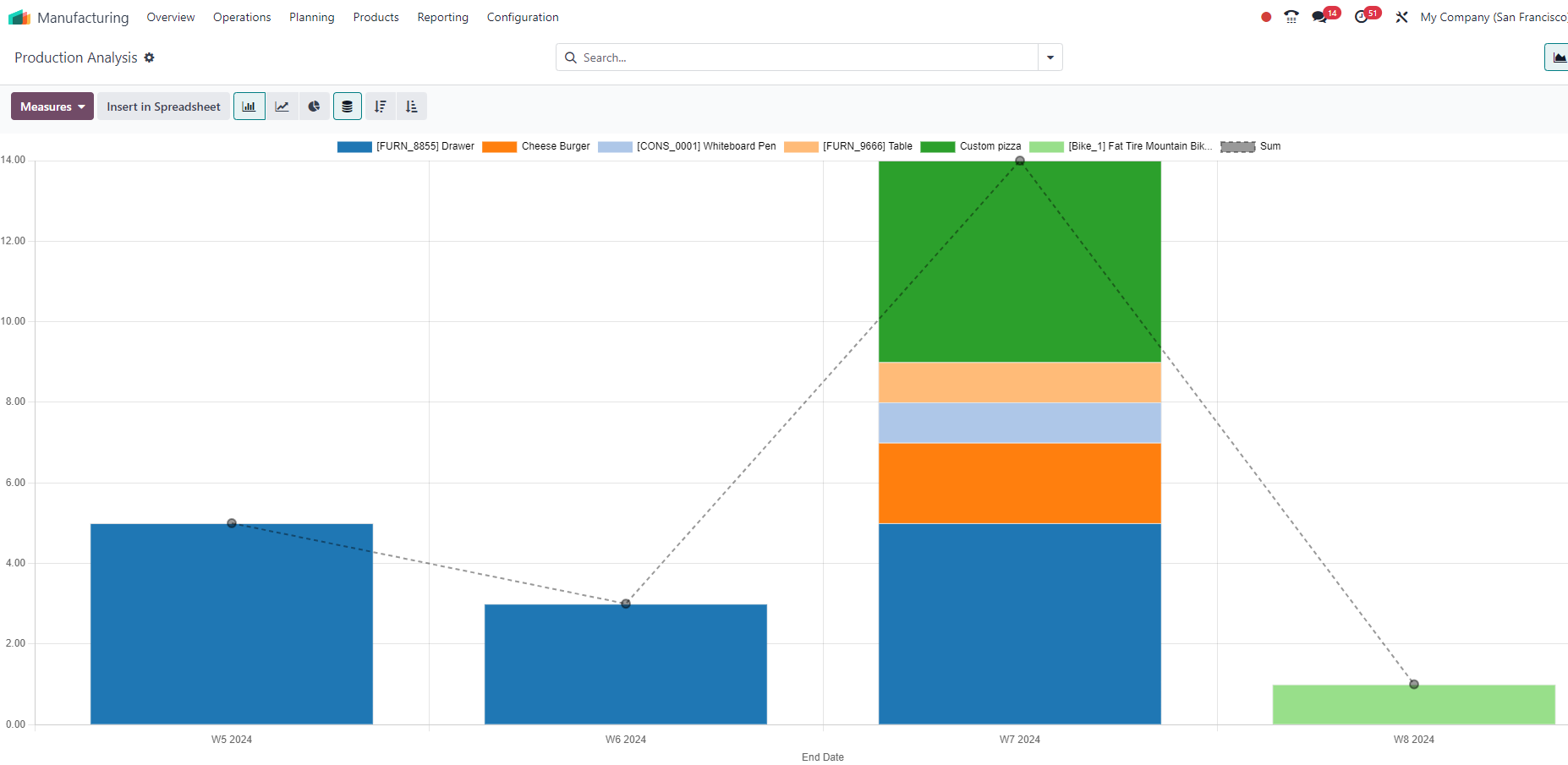

Odoo generate dedicated reports for manufacturing operations to identify opportunities, track progress, and refine processes, we will be able to get each operations analytical reports i.e. graph and pivot view.

- Production Analysis Report

- Overall Equipment Effectiveness (OEE) Report

- Work Orders Report

Conclusion:

Manufacturers today face numerous challenges, from increasing competition to changing customer demands. Implementing a comprehensive ERP system like Odoo can significantly improve manufacturing processes, drive efficiency, and boost competitiveness. By leveraging its powerful features and modules, manufacturers can streamline operations, reduce costs, and ultimately deliver better products to their customers.